Effective Wine Cellar Insulation: Learn from an Seattle Expert

Proper insulation is a key feature for residential and commercial wine cellars. Make sure you’re working with a Seattle expert like Classic Cellars.

Working with a builder who does not fully understand the effect of poor insulation on the wine can result in huge problems like wine faults and even structural damage to your wine room. At Custom Wine Cellars Seattle, we have extensive technical knowledge and expertise in wine cellar insulation. If you want to ensure that your residential or commercial wine room in Seattle is safe, let us help you.

A Wine Cellar Insulation Expert Can Prevent Damaging Wine Storage Environment: How a Wine Cellar Insulation Expert in Seattle Can Prevent it

Unstable conditions will cause your wines to have off-flavors and aromas. Wine quickly deteriorates if you store it in a place where there is poor insulation. Insulating the wine room is an integral aspect of wine cellar construction. Just like the wine cooling system, insulation plays a significant role in preserving the bouquet of your wines before they are ready for consumption.

If you do not want to put your wines at risk, you must hire a builder who understands and knows the importance of sealing your wine room. At Custom Wine Cellars Seattle, we always make sure that our client’s wine cellars are installed with a vapor barrier and correct insulation before the installation of the racking, wine refrigeration system, flooring, door, and lighting.

Correct Wine Cellar Insulation and How it Can Save Your Wine Collection

Proper vapor barriers are an essential part of proper wine cellar insulation. Make sure you have Seattle’s best working on your project.

Creating an airtight seal is one of the factors that contribute to the efficiency and effectiveness of a wine cellar in preserving your prized wines. Keep in mind that a technical expert should do this.

Achieve the Optimum Conditions Essential for the Graceful Aging of Your Wines

Installing a vapor barrier and insulating the room are standard procedures followed by master builders in Seattle, including Custom Wine Cellars Seattle.

A vapor barrier is necessary for a climate-controlled environment. It is installed on the warm side of the room. Its role is to prevent warm air from entering your wine room. Building a refrigerated wine cellar without a vapor barrier will cause condensation to build up and mold to grow.

Moreover, wine cellar insulation should be done correctly to prevent fluctuating temperatures and varying humidity levels. This process stops the cold air from the cooling unit from escaping the wine cellar. It also prevents the warm air from entering.

Effects of Extreme Changes in Temperature and Humidity Levels

There are many types of insulation for the many types of wine storage systems. Your expert at Custom Wine Cellars Seattle will help you make the right choice.

Extreme changes or imbalances in the wine cellar conditions can cause wine damage. Excessive heat can cause wine oxidation. To avoid this, the temperature in your wine cellar must fall between 55 to 65 degrees Fahrenheit.

Varying humidity levels will result in the formation of condensation, which can trigger mold growth. Mold can damage the wine labels, racks, and the structural integrity of your wine cellar. It can also grow on the cork and contaminate the wine.

Methods of Wine Cellar Insulation: Pros and Cons

The R-value is the measurement of the ability of a material to resist heat transfer. Insulation is an effective way that prevent this from happening. The R-value depends on the composition of the product. With many insulation methods available, it is crucial that you seek the help of an expert.

Fiber Glass Batt Insulation

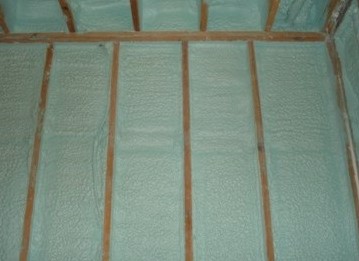

Custom Wine Cellars Seattle recommends that your wine room should have at least R-13 insulation value. The fiberglass batt insulation can provide this R-value. If you go for this option, there must be a 6-mil plastic vapor barrier installed on the warm side of your wine cellar walls.

The fiberglass insulation is commonly placed between each stud. It is the least expensive option but keep in mind that when poorly installed its efficiency will decrease. It must be done by a knowledgeable company to ensure that no small gaps are left.

Rigid Foam Insulation

Another material that we use for insulating refrigerated wine rooms is rigid foam or polystyrene. Like the fiberglass batt insulation, using a plastic vapor barrier is also required. To achieve the R-19 insulation (better than insulation created using the fiberglass batt). We use two layers of polystyrene (1 ½” thick) for better efficiency.

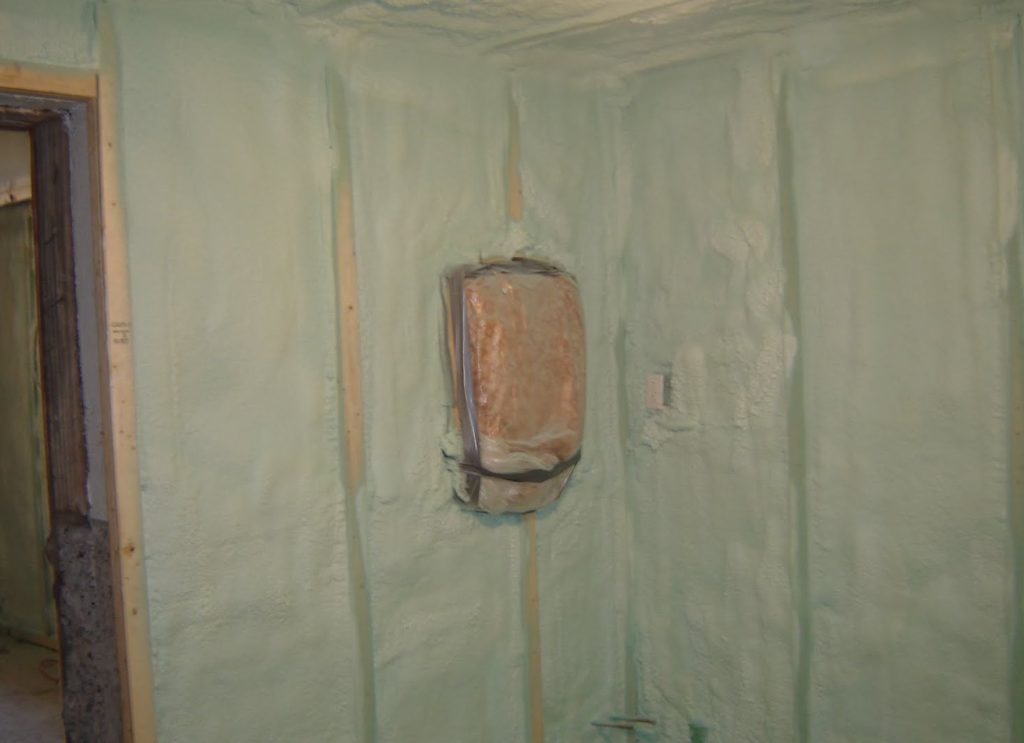

Polystyrene is also easy to install. However, if you have pipes or wiring that has to pass through a wall in your wine cellar, we have to cut the insulation board and place it around them. We can also wrap them in rigid foam. We always ensure that all of the gaps are filled with spray foam.

Closed-Cell Spray Foam: the Best Wine Cellar Insulation According to Experts in Seattle

The closed-cell spray foam insulation is the most reliable and recommended type of insulation by expert custom wine cellar builders. It has a compact structure, which expands to seal the gaps, creating an airtight seal. It is the best way to prevent air leakage.

It is also known to maximize the R-value in shallow cavities of the walls and ceiling, which helps increase the structural integrity of your wine cellar. Other advantages of the polyurethane closed-cell spray foam include

- Less prone to damage because of its high resistance to water

- Ability to prevent dust and pollen from entering the wine room

- Energy efficient

- Allows you to choose a cooling unit that is smaller in size to cool your wine cellar

- Prevents your wine refrigeration system from working hard

Master builders in Seattle, including Custom Wine Cellars Seattle, highly recommend closed-cell spray foam insulation because of its many benefits.

Insulation for the Door and Flooring

Insulation can be the unsung hero of the wine cellar. If it’s done right, you’ll never think about it. If it’s done wrong, it’ll give you nightmares.

To create an airtight seal around the door, we use an exterior grade wood that has 1 ¾” thickness and is constructed using the LVL technology. For the glass door, use thermally insulated glass panels. Door insulation is done by equipping it with weather stripping and an automatic bottom. These sealing components will aid in keeping the optimum conditions in your wine cellar in Seattle.

The insulation for flooring above ground is R-30. We recommend a liquid vapor barrier for flooring on a slab.

Protect Your Investment by Working with an Expert in Wine Cellar Insulation in Seattle

If you want to be worry-free on your next wine cellar installation project in Seattle, work with Custom Wine Cellars Seattle. Our team is known as one of the most reliable insulation experts in Washington State and the surrounding areas.

Need help? Contact us at +1 (206) 792-9912 or fill out the form at the top of the page. We’re excited to talk about your custom wine cellar!

?>)